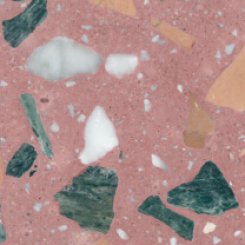

Halmann Vella manufactures cement-based architectural terrazzo blocks using a block casting plant. The casting process involves mixing, vibration and vacuum to ensure a high-quality homogeneous mix. Following casting and the standard curing time, the blocks measuring 3m x 1.2m x 0.7m are ready for further processing. The blocks can be transformed into slabs or organic 3D elements. The size of the block lends itself to the creation of large format tiles, vanity tops, counters, toilet cubicals and curbs at a lower cost and better quality, when compared to casting into individual moulds. This method is by far the most cost-effective manner of producing stairs and cladding.

A versatile terrazzo cement composite surface design is ideal for the following applications;

Ventilated façade cladding, stairs, internal cladding, floors, washroom and shower trays, custom shapes, large formats and cut to size